In the interest of public safety when working at heights this article clarifies the current status of the Australian Standards roof anchor point testing requirements, compliance, status and regulations as well as providing recommendations on the way forward. Unfortunately, height safety products and roof anchor points are currently unregulated as part of legislation, however do come under the SafeWork Australia and SafeWork NSW falls code of practice for products reassurance and Australian Standard conformity. 2024

Roof anchor point testing requirements and regulations are clarified in the SafeWork NSW government fact sheet. It was updated in August 2019, this document outlines roof anchor standards, testing, compliance, certification, and regulations. As noted in the document “Each anchorage point should comply with the requirements of AS/NZS 1891:4 Industrial fall-arrest systems and devices selection, use and maintenance.” as per falls code

As clearly outlined in the FALLS CODE OF PRACTICE roof anchors and static lines and ladder access brackets must comply to the following standards;

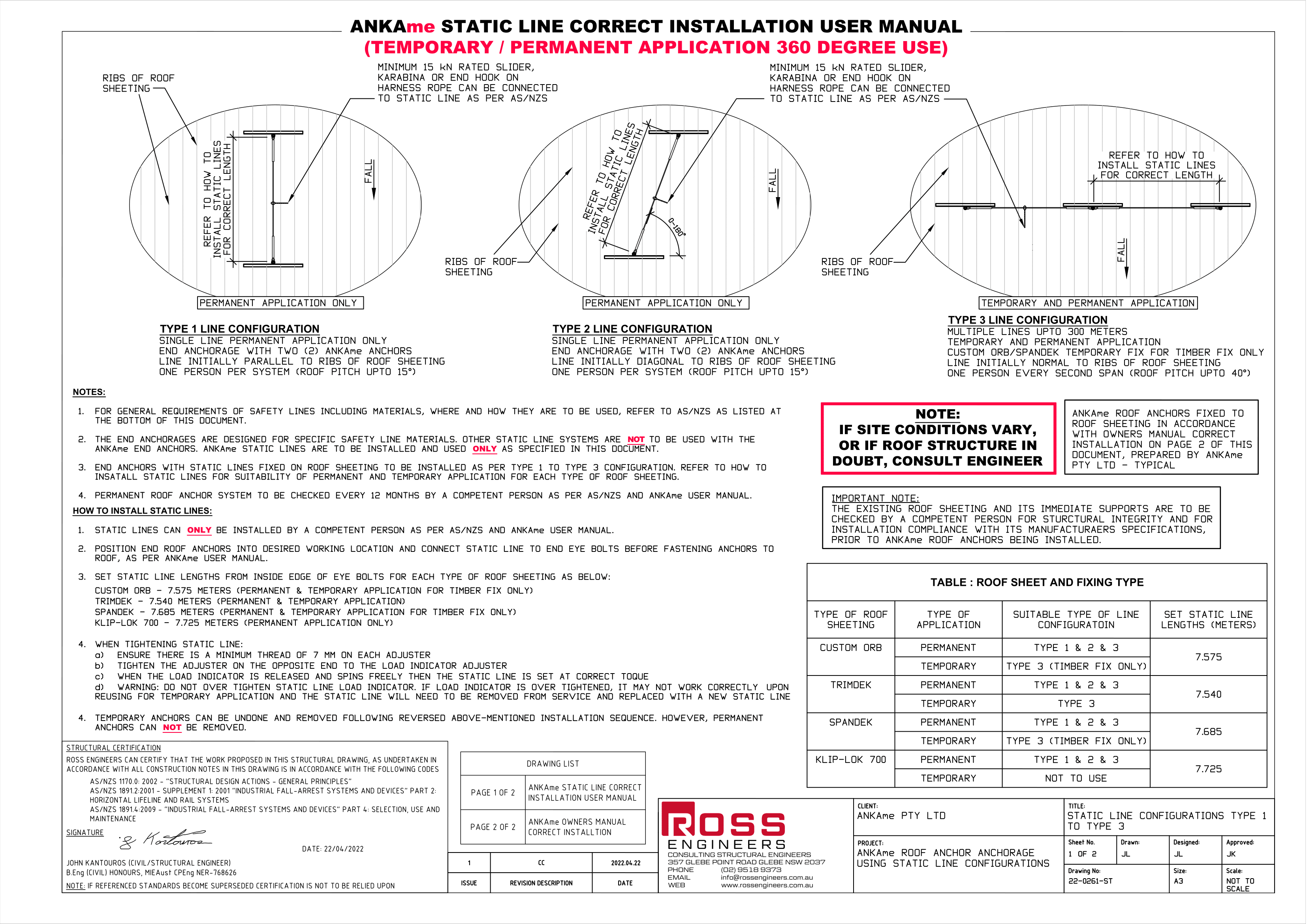

- AS/NZS 1891.4:2009: Industrial fall-arrest systems and devices – Selection, use and maintenance ( Roof anchors )

- AS/NZS 1891.2 Supp 1:2001: Industrial fall-arrest systems and devices – Horizontal lifeline and rail systems – Prescribed configurations for horizontal lifelines ( Roof anchor static line systems )

- AS/NZS 1657:2018: Fixed platforms, walkways, stairways and ladders – Design, construction and installation ( Ladder access brackets )

The following points should also be noted for industry safety and product compliance awareness:

- NOTE: 15kn of load is approximately 1500kg of load - tested in the direction of a fall as per AS/NZS 1891.4:2009

- NOTE: there is NO dynamic testing in AS/NZS for surface mounted roof anchors ( eg. dropping a 100kg weight approximately 2 meters )

- NOTE: be aware that stainless steel roof anchors are not compatible with direct contact to Colourbond or Zincalume roof sheeting and Aluminium fasteners / rivets are also NOT compatible with Stainless Steel, refer to blue scope steel compatibility chart HERE

TODAY OUR INDUSTRY HAS A LOT OF SERIOUS PERSONAL SAFETY CONCERNS AND INDUSTRY CONFUSION DUE TO THE FOLLOWING FACTORS:

1. Our industry has no formal regulatory body which means no government body is responsible for product testing and compliance

- Despite the fact there is a standard AS/NZS 1891:4 there is no requirement to follow because;

- This industry is currently unregulated, and no industry body appears to have a mandate to regulate the standards and ensure product compliance.

- This flags very serious issues of potential harm at a height caused by non-compliant products!

- As an industry, no government body appears responsible for ensuring compliance by manufacturers of roof anchor products.

- A key concern in compliance is the simple and basic 15Kn Static Load (Approximately 1.5 tonnes of load and equates to the weight of a small car)

- 70% of products on the Australian market fail the 15Kn static load requirement test which is ludicrous and poses a huge risk of serious harm and potential death concerns that comes with an unregulated industry

- ANKAme roof anchors have proudly been tested for the 15Kn static load by a division of SafeWork NSW (NATA accredited specifically for testing roof anchor points to AS/NZS 1891.4 2009 Certificate of Accreditation)

2. An Unregulated Industry Lets Manufacturers who Falsify Information go Unchecked

- We believe that our industry is rife with misinformation and some manufacturers undertake practices where they falsify product testing and compliance information via certain committee groups.

- An unregulated standard allows some manufacturers to put their commercial interest before “the safety of a human life connected to a safe roof anchor point” because they go unchecked.

- False and misleading advertising is being distributed in our industry to suppliers, installers and end-users.

- Most manufactures cannot provide adequate verified test reports for their product and instead provide in-house product certificates which are not independently validated or compliant.

- We also believe many manufactures falsify their testing procedures by adding additional fixings to the roof anchor and roof sheeting during testing rather than following their own product installation user guide.

- An unregulated industry puts people’s lives at risk and presents an untenable situation which must be addressed

3. The 5532 Standard is completely restrictive, impractical and unethical

- The current 1891.4 2009 standard includes installation by a competent person. As noted in the SafeWork NSW Fact sheet above.

- Please note, the 5532 standard was crafted by some roof anchor manufactures through a certain committee group to manipulate our industry for their own commercial interest because their products don’t meet our current Australian standard testing and compliance requirements that already exist in AS/NZS 1891.4:2009 as referenced in the SafeWork Australia and SafeWork NSW falls code.

- Rather than making safe products and procedures, some companies in our industry seek to monopolise the industry for their own commercial advantage.

- If property owners and workers are forced by the 5532 standard, to have a company installer for every roof anchor point it could force owners to avoid the extra cost and continue at their own risk and jeopardise their safety. This is a scenario we are all trying to avoid.

- Demanding only manufacturer company installers can install is a very expensive extra cost in this industry and not logistically possible in rural and remote areas. Some companies are also charging up to $2,200 just to install 1 roof anchor point which is ludicrous and wrong. It is an unnecessary extra expense for the customer and users.

- Some roof anchor companies can also take up to 30 days to reply to a customer request for installation, due to lack of understanding.

- The 5532 standard does not protect the customer nor the end-user in any circumstance.

- The 5532 standard also revised the 15Kn static load testing from achieving the 15Kn load to having to hold the load for 3 minutes, in reflection to European standards which are completely different from our own Australian structures and materials?

- ANKAme has had our products tested and approved by a division of SafeWork NSW (NATA accredited for testing roof anchors to AS/NZS 1891.4; 2009, table 3.1, 15Kn of static load) the load was tested and held for 2:30 minutes. The change in 5532 to now hold the static load for 3 minutes is again unnecessary and has no advantages whatsoever

4. Installers are confused about what products DO and DO NOT comply which directly impacts their safety at heights and risk

5. Insurances for manufacturers and Installers continue to increase annually due to the amount of non-compliant roof anchor products flooding the market

6. We cannot reference European testing methods because European structures and materials are all different to Australian roof structures and materials

- European testing methods are not applicable because we have Australian Structures and Australian materials. European structures and materials are different and therefore not comparable.

- Certain committees claiming that drop testing a 100Kg weight 2 meters is sufficed and follows European standards (when we clearly have Australian roof materials and structures) and we have AS/NZS ( 15kN of load, that's approximate 1,500kg = 15kN )

WHAT THE AUSTRALIAN ROOF ANCHOR INDUSTRY REQUIRES?

Our industry needs confidence in product testing and certification;

- 15Kn of static load – approximate 1.5 tones of load from roof anchor point during testing – hold load 2:30 minutes AS-NZS Compliance

We require governance from a dedicated division of SafeWork Australia or SafeWork NSW or the ACCC or another Independent Government body to ensure compliance of all products

- We need a regulatory body that can test and advise manufactures of roof anchor points if they DO or DO NOT comply with AS/NZS 1891.4:2009 standard, as referenced in the falls code, including the OHS legislation, including the building code act and including the 2010 common law act.

Roof anchors should be able to be installed by any competent person giving property owners and workers the option to either;

- Install a temporary or permanent roof anchor system themselves as per the manufactures user guide and installation manual and AS/NZS 1891.4; 2009 selection use and maintenance, “installed by a competent person, as per manufactures user guide and installation instructions.

- Have an industry expert come to assess and install permanent or temporary roof anchors at an additional service fee

It would be great if SafeWork Australia should provide a “basic competency-based roof anchor point installation online training course" or reference alternative compliant manufacture online video training course.

THE RECOMMENDED SOLUTION AND WAY FORWARD

Remove the confusing, misguided and derelict AS/NZS 5532: 2013 ( DOUBLE UP standard )

Remove AS/NZS 5532 from service because having two different standards for testing and then for installation just confuses industry, builders, architects, property managers, consultants, building superintendents, building certifiers, users and property owners, as clearly seen over the last 8 years since 5532 was published in 2013, (only 4 years after 1891.4:2009 was published in 2009) The standard has not worked since being released and will not work anytime in the future

SafeWork NSW submit a HAVE YOUR SAY with an industry forum

- An industry open forum would allow everyone involved to review and develop a realistic and safe way forward for our industry that reduces risks and personnel safety concerns

- We would expect all industry bodies and committees to be involved including HIA / MBA / MRCCA / MPA / TRADES AND RELATED INDUSTRY

Update current standard AS/NZS 1891.4:2009 to AS/NZS 1891.4:2022 to include the following additional test requirements which ensure safety and reduce risk to personnel;

- 15kN of static load to the roof anchor must be achieved and held for 2:30 minutes, as per table 3.1, 1891.4:2009 of the current standard of compliance.

- The roof anchor shall be tested in the direction of a fall down the direction of the roof sheeting and from left to right and from right to left (Tested 180 degrees from the roof anchor location).

- Roof anchors that achieve the 15kN static load are currently rated to 1 person per system but should in theory be able to hold up to (2 persons per roof anchor system).

- Roof anchors that achieve the 15kN static load can be used for static line use 1 person per system but should in theory be able to hold up to (s persons per roof anchor system).

- Only static load testing is required, (drop testing) or dropping a 100kg weight at 2 meters is used for shock absorbing lanyard testing and has NOTHING to do with testing roof anchor points.

- Roof anchors shall be used for abseiling that comply with static load of 15kN and this does not include energy-absorbing anchors.

- Ongoing testing of roof anchors is not required once roof anchor has been static load tested to 15kN.

- Pull out test of as installed roof anchors is not required. If the roof anchor meets the 15kN static load test and the permanent roof anchors have been inspected by a competent person every 12 months.

- Product warranties are not required on the basis that the manufacturers would provide the customer with user and maintenance information along with a user manual on each roof anchor and for all permanent roof anchors, includes following warrantee guarantees as specified by law.

- We advise that all roof anchor points should be assessed and inspected by a competent person every 12 months, as per current standard.

- Specified fastenings must meet breaking load minimum requirements.

- Specified fastenings must be sold with every roof anchor.

- Batch numbering and serial numbering must be on every roof anchor for product traceability.

- User manual must come with and be provided with each roof anchor.

- Manufacturer must provide some form of installation method and user guide with each roof anchor sold. Roof anchors can be installed by a competent person as per manufacturers selection use and maintenance user guide.

- Manufacturer must provide safe working documents for products installation, plus product test compliance certificates signed by an engineer or certified person and related client hand over documents, for permanent roof anchor installation.

- Manufacture must NOT falsify any product testing or technical information related to their products.

- Manufacture MUST provide the required testing certificates signed by a competent testing authority, engineer or approved by a division of SafeWork Australia

- Remove any roof anchor testing less than 15kN of static load (deemed as unsafe)

- Any ongoing roof anchor installations from 2024 must comply with new updated standard

- Any non-complying products would have 2 years from date of publication to comply with updated standard, this includes any as installed roof anchor points

Andrew Sweeny, a height safety industry

expert wrote a great article on LinkedIn on January 20, 2017 and it is

such a shame there is still “Ongoing Confusion” on this matter and all

his points remain valid today.